Another common characterisation method is the t-plot method. First, make sure the data is imported by running the previous notebook.

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the adsorbate on the surface of the adsorbent. This process differs from absorption, in which a fluid (the absorbate) is dissolved by or permeates a liquid or solid (the absorbent), respectively. Using the t-method, adsorption data can be plotted as a t-curve: the volume of nitrogen adsorbed vs. T, the statistical thickness of an adsorbed layer on a nonporous reference surface at a corresponding relative pressure.

This method requires, besides the isotherm, a so-called thickness function which describes the thickness of adsorbate on a non-porous surface. It can be specified by the user, or otherwise the 'Harkins and Jura' thickness model is used as default. When the function is called without any other parameters, the framework will attempt to find plateaus in the data and automatically fit them with a straight line.

Let's look again at the our MCM-41 pore-controlled glass.

T-plot Adsorption

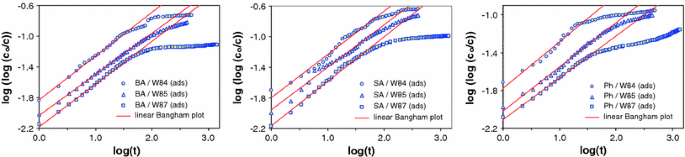

If we plot a graph between log (xlm) on y-axis (ordinate) and log p, on x-axis (abscissa), straight line will be obtained. The slope of the line is equal to 1/n and the intercept is equal to log K. Freundlich’s adsorption isotherm fails at high temperature. BET plot is dependent on the adsorption system (both adsorbent and adsorptive) and the opera-tional temperature. In view of this situation, it is strongly recommended 14 that the BET monolayer capacity, n m, should be derived from the best linear fit for that part of the isotherm. A typical plot of ln k/ T vs. 1/T (Eyring equation plot) In general, the ¦G.values are positive at all temperatures suggesting that adsorption reactions require some energy from an external source to convert reactants into products.

The first line can be atributed to adsorption on the pore surface, while the second one is adsorption on the external surface after pore filling. Two values are calculated for each section detected: the adsorbed volume and the area. In this case, the area of the first linear region corresponds to the pore area. Compare the specific surface area obtained of 350 (m^2) with the 360 (m^2) obtained through the BET method previously.

In the second region, the adsorbed volume corresponds to the total pore volume and the area is the external surface area of the sample.

We can get a better result for the surface area by attempting to have the first linear region at a zero intercept.

A near perfect match with the BET method. Of course, the method is only this accurate in certain cases. Let's do the calculations for all the nitrogen isotherms, using the same assumption that the first linear region is a good indicator of surface area.

We can see that, while we get reasonable values for the silica samples, all the rest are quite different. This is due to a number of factors depending on the material, with ultramicroporous condensation and adsorbate-adsorbent interactions having an effect on the thickness of the layer. The t-plot requires careful thought to assign meaning to the calculated values.

Since no thickness model can be universal, the framework allows for the thickness model to be substituted with an user-provided function which will be used for the thickness calculation, or even another isotherm, which will be converted into a thickness model.

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the adsorbate on the surface of the adsorbent. This process differs from absorption, in which a fluid (the absorbate) is dissolved by or permeates a liquid or solid (the absorbent), respectively. Using the t-method, adsorption data can be plotted as a t-curve: the volume of nitrogen adsorbed vs. T, the statistical thickness of an adsorbed layer on a nonporous reference surface at a corresponding relative pressure.

This method requires, besides the isotherm, a so-called thickness function which describes the thickness of adsorbate on a non-porous surface. It can be specified by the user, or otherwise the 'Harkins and Jura' thickness model is used as default. When the function is called without any other parameters, the framework will attempt to find plateaus in the data and automatically fit them with a straight line.

Let's look again at the our MCM-41 pore-controlled glass.

T-plot Adsorption

If we plot a graph between log (xlm) on y-axis (ordinate) and log p, on x-axis (abscissa), straight line will be obtained. The slope of the line is equal to 1/n and the intercept is equal to log K. Freundlich’s adsorption isotherm fails at high temperature. BET plot is dependent on the adsorption system (both adsorbent and adsorptive) and the opera-tional temperature. In view of this situation, it is strongly recommended 14 that the BET monolayer capacity, n m, should be derived from the best linear fit for that part of the isotherm. A typical plot of ln k/ T vs. 1/T (Eyring equation plot) In general, the ¦G.values are positive at all temperatures suggesting that adsorption reactions require some energy from an external source to convert reactants into products.

The first line can be atributed to adsorption on the pore surface, while the second one is adsorption on the external surface after pore filling. Two values are calculated for each section detected: the adsorbed volume and the area. In this case, the area of the first linear region corresponds to the pore area. Compare the specific surface area obtained of 350 (m^2) with the 360 (m^2) obtained through the BET method previously.

In the second region, the adsorbed volume corresponds to the total pore volume and the area is the external surface area of the sample.

We can get a better result for the surface area by attempting to have the first linear region at a zero intercept.

A near perfect match with the BET method. Of course, the method is only this accurate in certain cases. Let's do the calculations for all the nitrogen isotherms, using the same assumption that the first linear region is a good indicator of surface area.

We can see that, while we get reasonable values for the silica samples, all the rest are quite different. This is due to a number of factors depending on the material, with ultramicroporous condensation and adsorbate-adsorbent interactions having an effect on the thickness of the layer. The t-plot requires careful thought to assign meaning to the calculated values.

Since no thickness model can be universal, the framework allows for the thickness model to be substituted with an user-provided function which will be used for the thickness calculation, or even another isotherm, which will be converted into a thickness model.

For example, using a carbon black type model:

T Plot Adsorption Analysis

Isotherms which do not use nitrogen can also be used, but one should be careful that the thickness model is well chosen.

T Plot Adsorption Meaning

More information about the functions and their use can be found in the manual.